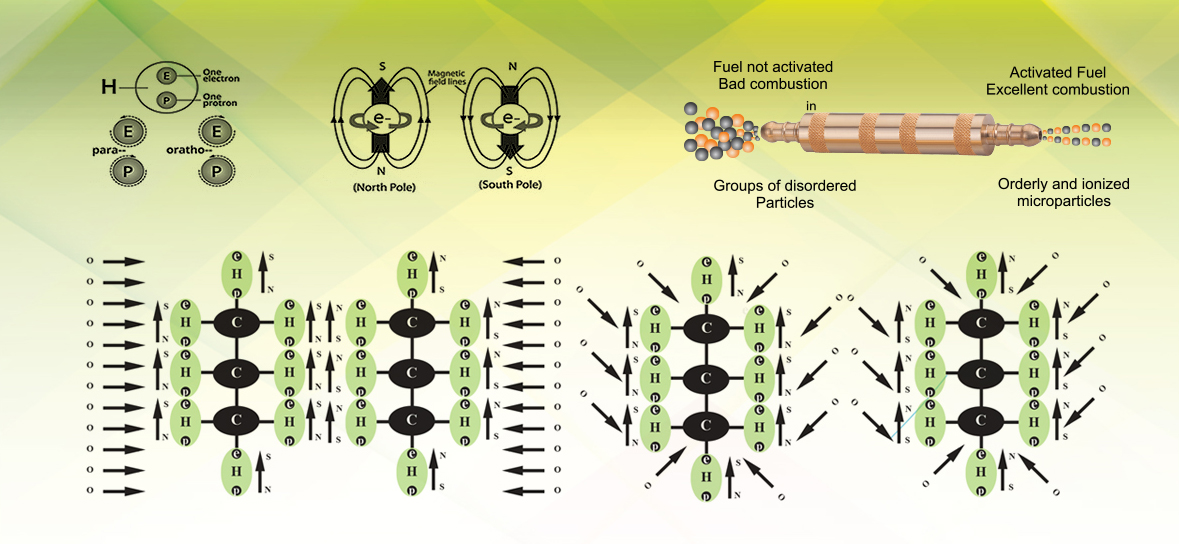

Under very high intensity magnetic flux(of specific pattern & strenght), The hydrogen electron reverts its direction and result into reversal of the magnetic poles of the hydrogen atoms temporarily (Para to Ortho). Hence the intermolecular forces changes to repulses forces, thus breaking the cage structure of hydrocarbon.This allow oxygen molecule to penetrate and oxidize carbon completely,resulting into maximum enrgey liberation.

"Every fuel consists of large hydrocarbon chain molecules, which are required to be broken into smaller fragments and ions to burn it completely .Our patented fuel Conservators embodies an art of processing fuel molecules through the use of an ultra-strong variable magnetic flux field imposed at a particular portion of a flow path traveled by fuel molecules towards the place of combustion. The angle, orientation and strength of flux field are finely adjusted according to the molecular structure of the hydrocarbon fuel. This technology in particular utilizes specific apparatus which impose a magnetic flux on fuel molecules before combustion in order to render the fuel molecules more readily combustible.

It consists of a co-axial magnetic circuitry fused inside an extra strong metallic body. The coaxially aligned permanent magnetic array inside this device is made from patented combination of rare earth magnetic core and minerals ores. . The property of these special compound ores is to minimize the inter-molecular forces between corresponding hydrocarbon molecules and break these large fuel molecule groups into smaller charged individual molecules.

Under this very high intensity magnetic flux (of specific pattern & strength) , the Hydrogen electron reverts it’s direction and results into reversal of the magnetic poles of the hydrogen atoms temporarily (Para to Ortho) . Hence the intermolecular forces changes to repulsive forces, thus breaking the cage structure of Hydrocarbon. This allows oxygen molecule to penetrate and oxidize carbon completely, resulting into maximum Energy liberation.

As a result fuel particles come out of this device with greater repelling force to easily combine with oxygen, forming extra charged combustion mixture. This fuel mixture burns with more thermal efficiency producing maximum heat. Due to this complete combustion process, wastage fuel as un burnt gases and vapors is minimized to zero. And hence we save up to 25% of Hydrocarbon fuel. After years of Research and practical experimentations results, we have advanced our device configuration and aperture of the circuitry, to achieve maximum results."

BENEFITS :

OBSERVATION :

Dust in exhaust gas from a boiler was measured by both weight and concentrate methods. It was found that at the same weight of dust contained in exhaust gas, the exhaust gas generated after the magnetizing treatment according to these devices exhibited in higher value in concentration than that generated without magnetization. This fact that dust particles after magnetization are finer than those usually found, which in turn, means that oil particles are made finer by the magnetizing treatment of these devices.